Fiber-based hydrogels for designing viscoelastic responses in particle-based biomaterials that support embedded 3D printing

Fiber-based hydrogels for designing viscoelastic responses in particle-based biomaterials that support embedded 3D printing

Grewal, M. G.; Porter, L.; Helein, G.; Highley, C. B.

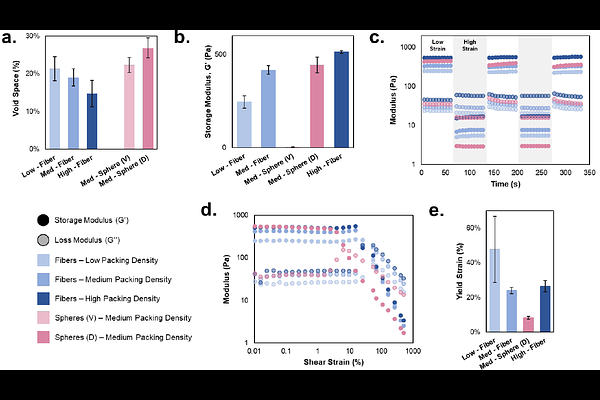

AbstractViscoelastic biomaterials that exhibit biomimetic responses to applied stresses are important in studying physiology and designing biomaterial scaffolds. Particle-based hydrogels offer potential for engineering viscoelasticity through design of both the component microparticles and their processing into bulk particle-based materials. When particles are not crosslinked to one another, particle movements in response to strain can potentially relieve applied stresses and facilitate the material\'s use in dynamic processes like bioprinting. In particle-based hydrogels based on spherical hydrogel microparticles (HMPs), particle movement is restricted by contacts with immediately adjacent HMPs. In comparison, fiber-based hydrogel systems leverage high-aspect ratio microfiber components with long-range interactions. Here, microfibers with aspect ratios of ~15:1 length:diameter are used to form particle-based hydrogels to compare how interparticle interactions at increased length scales alter properties compared to particle-based hydrogels based on spherical HMPs. Like particle-based hydrogels formed from spherical HMPs, those formed from fiber HMPs exhibit viscoelasticity, with shear-thinning and self-healing behaviors. But, fiber-based materials allow enhanced control over bulk stress relaxation times (T1/2 ~ 1-100+ s) across a range of applied strains ({sigma} ~ 2.5-50%) in a packing density-dependent fashion. Fiber-based systems relaxed stresses continually and to a greater degree at low strains in comparison to HMP systems. Dynamic interfiber interactions in fiber-based hydrogels also supported embedded printing where perfusable channels can be printed into fiber-based hydrogels stabilized by physical interfiber interactions. Taken together, fiber-based hydrogels offer opportunities for designing complexity into biomaterial scaffolds, including allowing control over viscoelastic properties through hydrogel design and control over heterogeneous 3D structures through embedded printing.