Production of Glycolic acid through Whole-Cell Bioconversion from PET Monomer Ethylene Glycol Using Engineered Corynebacterium glutamicum

Production of Glycolic acid through Whole-Cell Bioconversion from PET Monomer Ethylene Glycol Using Engineered Corynebacterium glutamicum

Mohammad, G. R.; Wong, F. T.; Lim, Y. H.

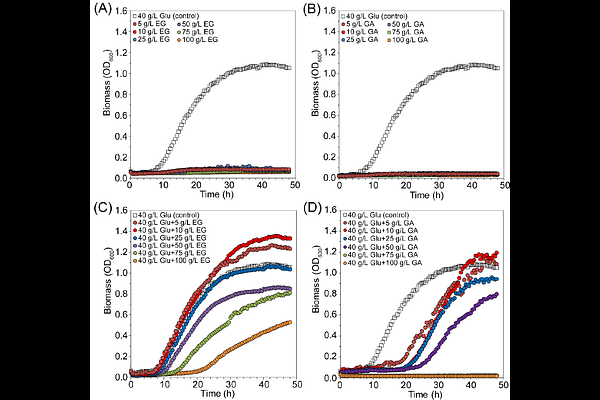

AbstractIn the last decade, the global warming and plastic pollution issue have driven research on developing a more sustainable platform for chemicals production from alternative feedstocks. Ethylene glycol (EG), a monomer of polyethylene terephthalate (PET) plastic, has a potential to become a renewable substrate for microbial production of value-added chemicals. This study presents a biotransformation platform using Corynebacterium glutamicum to produce glycolic acid (GA) from EG. C. glutamicum was engineered to express a heterologous EG oxidation pathway. Subsequent promoter engineering yielded strain FA4, producing 10.6 g/L GA from EG in 48 h. Implementation of a two-stage biotransformation strategy using resting cells further enhanced the GA production, reaching a cumulative GA titer of 98.8 g/L after a 72-h production. Finally, applying this platform to a simulated EG mixture from PET-degradation achieved a cumulative GA titer of 67.3 g/L over 72 h, highlighting the potential for valorizing plastic waste through this biotransformation platform. These findings establish C. glutamicum as an efficient biotransformation chassis for sustainable GA production from EG and offer a promising route for PET waste valorization into value-added chemicals.